Umshini wokunyathelisa we-tile kufanele ucabangele ukusebenza kahle kokusika, umnotho kanye nezindleko zokucubungula ngaphansi kwesisekelo sokuqinisekisa ikhwalithi yokucubungula.Okokuqala, thola inani le-back cut ngokusho kwesabelo ngemuva komshini onzima;okwesibili, khetha isilinganiso esincane sokuphakela ngokuya ngezidingo zokuqina kwendawo ecutshunguliwe;ekugcineni, khetha isivinini sokusika esiphezulu ngangokunokwenzeka ngaphansi kwesisekelo sokuqinisekisa ukuqina kwethuluzi.

Ukunqunywa kwenani elinqunyiwe Inani lokusika lihlanganisa ukujula kokusika (inani lokusika), isivinini sokuphotha (isivinini sokusika), kanye nezinga lokudla.Ezindleleni ezihlukene zokucubungula, imingcele yokusika ehlukene idinga ukukhethwa, futhi kufanele ihlelwe ohlwini lohlelo.Umgomo wokukhethwa okunengqondo kwenani lokusika uwukuthi: ngesikhathi somshini onzima, ukucindezela kwamathayela ngokuvamile kugxila ekuthuthukiseni ukukhiqiza, kodwa izindleko zomnotho nezokucubungula kufanele zicatshangelwe.Izimo ezivimbelayo, njll., khetha izinga lokuphakelayo libe likhulu ngangokunokwenzeka;ekugcineni unqume isivinini sokusika esingcono kakhulu ngokusho kokuqina kwethuluzi.Ngesikhathi sokuqeda kanye nokuqeda.

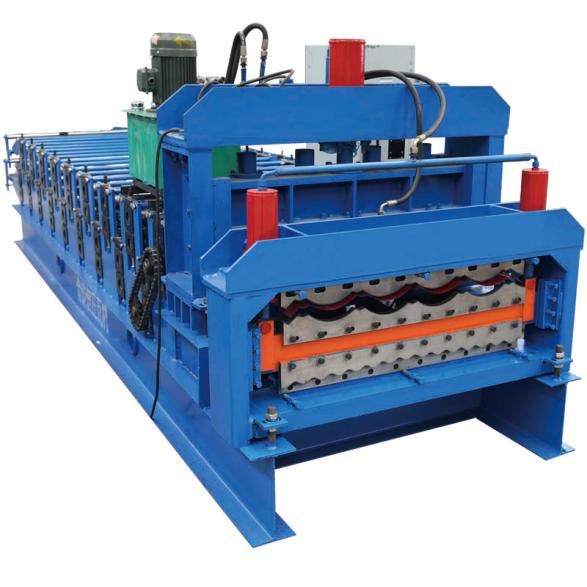

Ukuhlaziywa kokukhethwa kwama-props amathuluzi omshini wokucubungula we-tile press:

Lapho kusetshenziswa ukugaya phansi, ithuluzi lomshini wemishini yokunyathelisa yethayela lidingeka kuqala ukuze libe nendlela yokususa igebe, elingasusa ngokuthembekile igebe phakathi kwesikulufu sokudla kwetafula namantongomane, ukuze kuvinjelwe ukudlidliza okukhiqizwa phakathi nenqubo yokugaya. .Kuhle uma itafula liqhutshwa ngamanzi.Amathuluzi omshini we-CNC ngokuvamile asebenzisa ukugaya phansi, futhi imishini yokugaya ngesandla ngokuvamile isebenzisa ukugaya.Okwesibili, kuyadingeka ukuthi asikho isikhumba esiqinile ebusweni be-workpiece engenalutho, futhi uhlelo lwenqubo yesikhungo somshini kufanele sibe nokuqina okwanele.Uma lezi zimo ezingenhla zingahlangatshezwana nazo, ukucindezela kwethayela okugaywa phansi kufanele kusetshenziswe ngangokunokwenzeka.

Isikhathi sokuthumela: May-18-2023